section-fcad2a3

Vapor Corrosion Inhibitor Solution

The key to SOGEC's success lies in its Vapor Corrosion Inhibitor (VCI) technology, which effectively combats corrosion by creating a protective molecular layer on metal surfaces. This proven method extends the serviceable life of your assets, safeguarding your investment and ensuring optimal performance for years to come.

By implementing SOGEC's IDS (Inhibitor Delivery System) solutions, you can rest assured that your aboveground storage tanks are shielded from the damaging effects of underside corrosion. This not only preserves the integrity of your infrastructure but also translates to significant cost savings in the long run, as you avoid the need for frequent repairs or premature replacement.

section-e9a4d85

Vapor Corrosion Inhibitor Solutions

Vapor Corrosion Inhibitor Solutions include the following

- In Service Tank

- Out of Service Tanks

- Roof Protection

- Pipeline Casing Protection

- Offshore Rigs / Platforms / FPSO's

- Equipment Preservation

- Spare Parts Protection

Our Vapor Corrosion Inhibitor Activities Include

section-b8c0b01

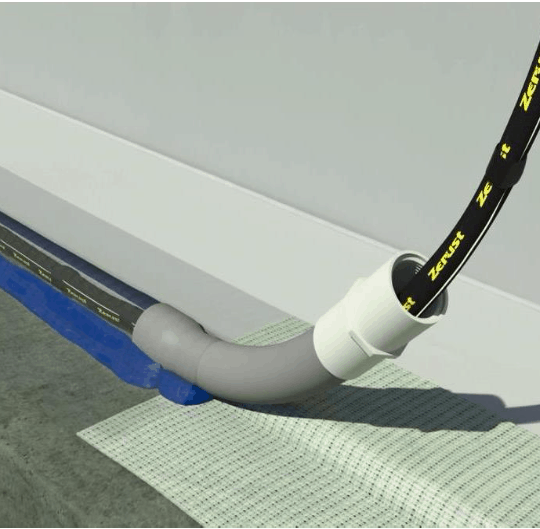

Chime Ring Dry IDS (Inhibitor Delivery System) solution is recommended for storage tanks with concrete or bitumen foundations. An innovative VCI/SCI (Soluble Corrosion Inhibitor) injection system is used to protect the tank bottom from corrosion. Perforated PVC pipe is installed around the entire annular chime area. The VCI dry sleeves are installed into the PVC pipe and the system is sealed to create an enclosure to contain the VCIs. The VCIs migrate and absorb onto the metal surface. The diffusion of VCIs provides corrosion protection in the critical 3 to 4 meters from the annular chime ring.

Chime Ring Injection IDS (Inhibitor Delivery System) solution is suitable for storage tanks with concrete, bitumen, or sand with liner foundations. Innovative VCI/SCI (Soluble Corrosion Inhibitor) injection system to protect the tank bottom from corrosion. As the inhibitor slurry is pumped into the perforated PVC chime ring system, the VCIs migrate and absorb onto the metal surface. Meanwhile, the liquid inhibitor slurry works to neutralize any contaminants it may contact on either the bottom plates or the foundation. The combination of VCIs and SCI works together to protect vulnerable areas of the tank bottom plates from corrosion.

Underside Injection IDS (Inhibitor Delivery System) solution is designed for tanks with compacted sand fill and Release Prevention Barriers (RPBs), double bottoms with sand between the old and new floors, or tanks sitting on a hard pad such as concrete or asphalt. As the slurry flows throughout the entire sand bed, the SCIs effectively neutralize contaminants on contact. Conversely, the VCIs emitted by the slurry migrate and absorb onto the metal surface. The VCIs permeate the sand bed through capillary action and gravity, providing protection to the entire tank floor.

The Underside Drip Tube IDS (Inhibitor Delivery System) is an innovative solution that protects tank bottom plates of single or double-bottom tanks during construction or new floor installation. A network of perforated PVC pipes with mesh sleeves is installed in rings on top of the tank liner in the sand foundation low-viscosity inhibitor slurry is pumped into the designated ring wall port(s) into the sand bed, and the perforated PVC pipe network distributes the slurry evenly throughout the system. The VCIs are released from the sand bed, protecting the metal bottom plates of the tank. The SCIs in the inhibitor neutralize contaminants in the sand bed. The injection port(s) can be used for future inhibitor injections.

IDS (Inhibitor Delivery System) system is designed to protect tank bottom plates during construction or new floor installation. This solution benefits tanks with concrete, bitumen, and compacted sand foundations with or without liners. Shallow trenches are cut into the foundation. Perforated, mesh-covered PVC pipes ‘are placed within the trenches and the trenches are then filled with sand and dry mesh sleeves of VCl inhibitor are installed into each of the pipe tubes. VCIs work to mitigate corrosion on the metal bottom plates of the tank

The Internal Flood IDS (Inhibitor Delivery System) solution is suitable for tank foundations of concrete, bitumen, or compacted sand with a liner. Low-viscosity inhibitor slurry is pumped into one or more temporary injection ports installed in selected locations through the tank floor. The VCI's emitted by the slurry migrate and absorb onto the metal surface. The SCls work to neutralize any contaminants they may contact with on either the bottom plates or foundation.

- Provides the option for replenishment.

- Can be combined with simple monitoring.

- Procedures to ensure the effectiveness of the solution.

- Corrosion protection for voids & interstices that are impossible to protect with other methods.

- Protection for tank bottoms plates and welds with little to no surface preparation.

- VCIs offer non-permanent corrosion protection at the molecular level that is safe and eco-friendly.

- Zerust's methods of VCI dispersion ensure.

- Uniform distribution. The service life of the tank bottom can be increased. Significantly at a minimal cost.

IDS (Inhibitor Delivery System) solutions are comprehensive and proven methods for protecting storage tanks with soil-side bottoms. IDS solutions reduce overall costs to tank farm owners while increasing corrosion efficacy. Tank operations do NOT need to be stopped during the inspection or maintenance of the SSB (Soil Side Bottom) solutions.